Understanding Ceramic Bearings Imagine factory

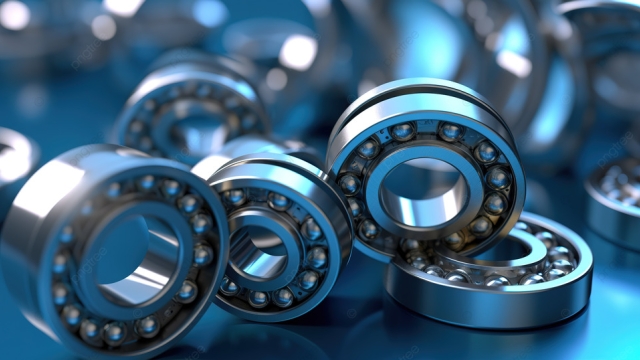

Imagine a factory where the hum of machinery is accompanied by the constant, soothing whir of perfectly operating parts. Now, consider the impact of a single faulty bearing in this environment. Such scenarios often lead to costly downtimes and repairs. This is where Ceramic bearings for industrial machinery come into play, offering a solution that enhances performance and reliability.

Understanding Ceramic Bearings

Ceramic bearings are made from advanced ceramic materials, notably silicon nitride. Unlike traditional steel bearings, ceramic bearings excel in various environments due to their superior properties. They are lighter, more resistant to corrosion, and capable of withstanding higher temperatures. This combination makes them ideal for applications in harsh industrial settings.

Advantages of Using Ceramic Bearings

One of the primary benefits of ceramic bearings is their durability. Unlike steel, ceramic materials do not rust or corrode, which is particularly beneficial in industries where exposure to chemicals is common. Additionally, ceramic bearings possess a lower friction coefficient, which translates to less energy consumption during operation. This can lead to significant cost savings over time, especially in large-scale operations.

Another compelling reason to consider ceramic bearings is their temperature tolerance. These bearings can operate effectively at temperatures exceeding 1200 degrees Fahrenheit, making them suitable for applications in high-heat environments such as aerospace and automotive industries. For instance, in high-performance engines, the reliability of ceramic bearings can lead to improved fuel efficiency and extended service life.

[IMAGE]

Applications in Industrial Machinery

Ceramic bearings find a wide range of applications in various sectors. In the manufacturing industry, they are used in conveyor systems, where their ability to handle heavy loads while minimizing friction is essential. Furthermore, in the food processing sector, ceramic bearings are favored due to their non-corrosive nature, ensuring compliance with health and safety regulations.

Another key area is the electronics industry, where precision is paramount. Ceramic bearings can be found in computer drives and robotics, where their lightweight and precision characteristics enhance performance and reduce wear on components. In wind turbines, these bearings contribute to energy efficiency and longevity, crucial in a field where maintenance can be both challenging and costly.

Cost Considerations and Longevity

While the initial investment in ceramic bearings may be higher than traditional bearings, their longevity often offsets this cost. Many users report that ceramic bearings last significantly longer than their steel counterparts, reducing the need for frequent replacements and maintenance. This is particularly beneficial in environments where machinery downtime can lead to substantial financial losses.

Moreover, the reduced friction associated with ceramic bearings can lead to lower energy costs. In industries where power consumption is a significant expense, transitioning to ceramic bearings can result in lower operational costs over time, making them a financially sound choice.

Future Trends in Bearing Technology

The future of bearing technology seems to be leaning more towards advanced materials like ceramics. As industries continue to prioritize efficiency and sustainability, the demand for innovative solutions will likely increase. Companies are investing in research and development to enhance the performance of ceramic bearings further, focusing on improving their capabilities and expanding their applications across various sectors.

In summary, the transition to Ceramic bearings for industrial machinery is not merely a trend but a strategic move towards enhancing operational efficiency and reducing costs. Their unique properties make them a compelling choice for a variety of applications, promising a robust return on investment for businesses willing to embrace this technology.