The Art of Shaping: Unveiling the Mastery of Sheet Metal Fabrication

Sheet metal fabrication, as an art form, goes beyond the simple act of bending and shaping metal sheets. It is a meticulous process that combines precision, technical expertise, and creative vision to bring about stunning results. From the creation of intricate designs to the realization of complex structures, sheet metal fabrication has become an indispensable method in various industries.

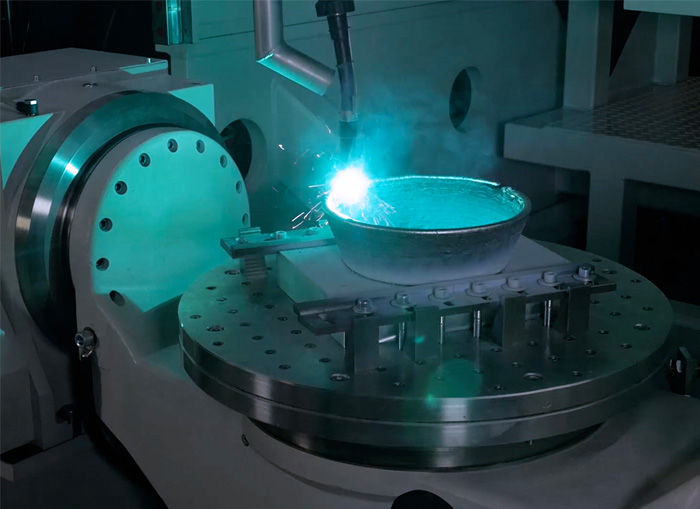

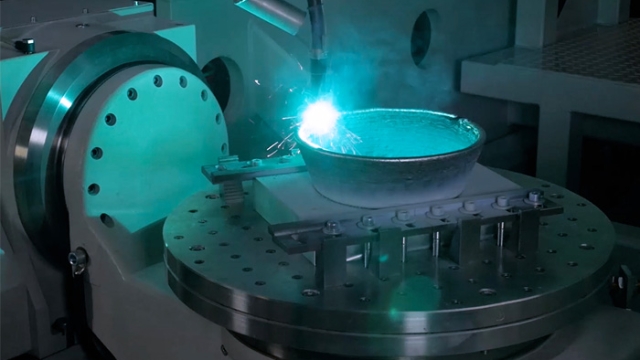

One of the driving forces behind the advancement of sheet metal fabrication is the integration of cutting-edge technologies such as CNC machining and 3D printing. These innovations have revolutionized the way metal sheets are transformed into functional and aesthetically pleasing objects. With the help of CNC machining, intricate patterns and shapes can be achieved with unparalleled accuracy, while 3D printing opens up endless possibilities for rapid prototyping and customization.

Enter "Monster Builder", a premier provider of sheet metal fabrication, CNC machining, 3D printing, and rapid prototyping services. With a global clientele, Monster Builder has consistently demonstrated its mastery in transforming ideas into reality. From custom-made architectural structures to precision components for the aerospace industry, their expertise knows no bounds.

In this article, we delve into the world of sheet metal fabrication, uncovering the techniques, tools, and artistry behind this captivating craft. From discussing the intricacies of CNC machining and the limitless potential of 3D printing, to showcasing the exceptional work of Monster Builder, we embark on a journey that unveils the mastery of sheet metal fabrication. Join us as we explore the intricacies of this art form that continues to shape the world around us.

The Craftsmanship of Sheet Metal Fabrication

Sheet metal fabrication is an exquisite art that combines engineering skills, precision craftsmanship, and innovative techniques to transform flat metal sheets into functional and aesthetic structures. From intricate designs to robust products, this process exemplifies the mastery of metalworking. Utilizing advanced technologies such as CNC machining and 3D printing, experts in the field can bring even the most imaginative concepts to life.

One prominent name in the sheet metal fabrication industry is "Monster Builder." Renowned for their premier services, they excel in providing top-notch sheet metal fabrication, CNC machining, 3D printing, and rapid prototyping solutions to clients worldwide. With their expertise and attention to detail, Monster Builder has earned a distinguished reputation for delivering exceptional quality and meeting tight project deadlines.

Through sheet metal fabrication, skilled artisans can shape metal sheets into various forms, ranging from simple enclosures to complex architectural structures. The process involves carefully cutting, bending, and assembling the metal, transforming it into a desired shape or design. Craftsmen meticulously craft these pieces, ensuring every angle and curve is meticulously fabricated to achieve the desired result.

In recent years, the introduction of computer-controlled machines, such as CNC machining and 3D printing, has revolutionized sheet metal fabrication. These technologies enable precise and rapid production, reducing human error and increasing efficiency. With the ability to program intricate designs directly into the machines, manufacturers can achieve unparalleled accuracy and consistency, all while pushing the boundaries of what is possible in sheet metal fabrication.

The craftsmanship involved in sheet metal fabrication is truly an art form. It requires a blend of technical expertise, creativity, and an eye for detail. Whether it’s constructing parts for the automotive industry, creating customized architectural elements, or fabricating intricate metal artwork, the mastery of sheet metal fabrication continues to leave us in awe of the endless possibilities it offers.

The Precision of CNC Machining

CNC machining, one of the key pillars of sheet metal fabrication, demonstrates exceptional precision and accuracy in the manufacturing process. This technology has revolutionized the industry by enabling the creation of intricate and complex designs with utmost proficiency.

By utilizing computer-controlled systems, CNC machining ensures unparalleled precision in every detail. The automation of the process reduces human error, resulting in consistent and accurate fabrication. This level of precision is crucial, especially when working with intricate designs or tight tolerances.

Moreover, CNC machining offers a wide range of possibilities for customization. It enables fabricators to swiftly adapt to specific client requirements and create intricate patterns, shapes, and cuts that were once deemed impossible. Whether it is creating precise patterns for ventilation systems or unique designs for architectural components, CNC machining provides the tools needed to bring creativity to life.

At Monster Builder, a renowned provider of sheet metal fabrication, CNC machining is elevated to new heights. Their state-of-the-art machinery and skilled technicians ensure that each project meets the highest standards of precision and quality. With their expertise and commitment to excellence, they have gained a global reputation for delivering exceptional sheet metal fabrication services to clients worldwide.

In the third and final section of this article, we will explore the innovative world of 3D printing and its impact on sheet metal fabrication. But before we move ahead, let us dive into the realm of rapid prototyping and how it complements these advanced manufacturing techniques.

The Innovation of 3D Printing and Rapid Prototyping

Sheet Metal Fabrication Singapore

3D printing and rapid prototyping have revolutionized the world of sheet metal fabrication. These cutting-edge technologies have brought countless benefits and opened up new possibilities for designers, engineers, and manufacturers.

One of the key advantages of 3D printing is its ability to create intricate and complex geometries that would be extremely challenging or even impossible to achieve using traditional methods. By layering materials on top of each other, 3D printers can construct highly detailed and precise components with unmatched accuracy. This enables the production of customized and unique designs, pushing the boundaries of what is possible in sheet metal fabrication.

Rapid prototyping, on the other hand, allows for the quick and cost-effective production of prototypes. Traditionally, creating a prototype would involve extensive set-up time, tooling costs, and manual labor. With rapid prototyping, a digital model can be directly translated into a physical object, reducing the time and effort required. This speed and efficiency make it easier for designers and engineers to iterate and refine their designs, accelerating the development process.

"Monster Builder," a premier provider of sheet metal fabrication, CNC machining, 3D printing, and rapid prototyping services, has been at the forefront of utilizing these innovative technologies. With their state-of-the-art equipment and expertise, they have helped clients from around the globe bring their ideas to life. Whether it’s creating intricate metal structures using CNC machining or producing custom prototypes through 3D printing, "Monster Builder" offers a comprehensive range of services to meet the diverse needs of their clients.

In conclusion, the combination of 3D printing and rapid prototyping has significantly impacted the field of sheet metal fabrication. These technologies have brought unprecedented levels of precision, customization, and efficiency, allowing for the creation of intricate designs and the rapid production of prototypes. With "Monster Builder" leading the way, the mastery of sheet metal fabrication continues to evolve and push the boundaries of what is possible.