Unleashing the Fermentation Fiesta: A Dive into Brewery Equipment

Are you ready to dive into the exciting world of brewery equipment? If you’re a beer enthusiast or simply curious about the art of brewing, understanding the tools and machinery behind the scenes is essential. Brewery equipment plays a crucial role in bringing our favorite beverages to life, from small microbreweries to large-scale operations. Whether you’re just starting your journey as a homebrewer or exploring the possibilities of opening your own brewery, this comprehensive guide will walk you through the different types of equipment and their functions. Join us as we take a closer look at brewery equipment and unleash the fermentation fiesta that awaits!

1. Understanding Brewery Equipment

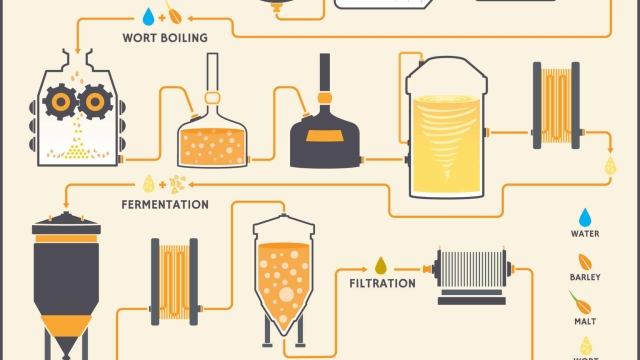

Brewery equipment plays a pivotal role in the craft beer revolution. So, what exactly is brewery equipment? It encompasses a wide range of tools and machinery used in the process of brewing beer. From the traditional equipment like fermentation tanks and brewhouses to the more sophisticated microbrewery equipment, these essential components are the backbone of any successful beer production.

Starting off with the basics, brewery equipment primarily consists of brewing vessels, such as mash tuns and lauter tuns, which are used for extracting sugars from malted grains. These vessels, often made of stainless steel or copper, provide the perfect environment for the mashing and lautering process, ensuring the essential sugars are separated from the grain husks.

To achieve the magic of fermentation, breweries rely on fermentation tanks, often referred to as fermenters. These vessels provide a controlled environment where yeast is added to the brew, converting the sugars into alcohol and producing that delightful range of flavors and aromas we associate with beer. These tanks are typically made of stainless steel or glass and are designed to maintain precise temperature and pressure conditions to enhance the fermentation process.

Finally, we have the microbrewery equipment, which has gained popularity with the rise of craft brewing. Microbreweries are smaller-scale breweries that produce a limited quantity of beer, often with a focus on unique and experimental flavors. Their equipment is designed to complement this artisanal approach, offering flexibility and versatility in brewing methods, such as smaller fermentation tanks, specialized brewing systems, and precise temperature control mechanisms.

Understanding brewery equipment is paramount for aspiring brewers and beer enthusiasts alike. By familiarizing ourselves with the essentials of brewery equipment, we can appreciate the craftsmanship and precision involved in the brewing process. From the traditional brewhouses to the innovative microbrewery equipment, each component contributes to the art and science of crafting the perfect pint.

2. Choosing the Right Microbrewery Equipment

When it comes to setting up your microbrewery, selecting the right brewery equipment is of utmost importance. Consideration should be given to various factors to ensure that your brewing process runs smoothly and efficiently. In this section, we will explore three key aspects to keep in mind when making your equipment choices.

Firstly, it is crucial to assess the capacity and production needs of your microbrewery. Understanding the volume of beer you plan to produce will help determine the appropriate size of your brewing equipment. Whether you are starting small or have ambitions for expansion, selecting equipment that aligns with your production goals is critical to avoid unnecessary complications down the line.

Secondly, carefully evaluate the specific brewing techniques and styles you aim to master. Each brewing process requires different equipment configurations, so investing in versatile and adaptable brewing equipment is advisable. By choosing equipment that can accommodate various brewing methods, you will have the flexibility to experiment and create a wide range of beer styles to please even the most discerning palates.

Lastly, give due consideration to the quality and durability of the brewery equipment you intend to purchase. Focus on selecting reliable, well-built equipment from reputable manufacturers. While cost is undoubtedly a factor, compromising on quality can lead to inefficiencies and increased maintenance costs in the long run. Prioritizing equipment that can withstand the demands of a microbrewery’s daily operations will contribute to the overall success of your brewing venture.

By considering the capacity, brewing techniques, and quality of the microbrewery equipment, you can make informed decisions that set your business up for success. In the next section, we will delve into the essential components of brewery equipment necessary for a smooth brewing process. Stay tuned!

3. Exploring Beer Brewing Equipment

In this section, we will dive deeper into the world of brewery equipment and explore the essential tools needed for beer brewing. Whether you are a professional brewer or a passionate home brewer, understanding the different types of brewery equipment is key to creating delicious brews.

-

Brew Kettle: The brew kettle is the heart of any brewing operation. It is where the brewing process begins, as it is used to boil the ingredients and extract flavors from the malt. Brew kettles come in various sizes, usually measured in gallons or liters, to accommodate different batch sizes. They are often made of stainless steel or copper, which offer excellent heat conductivity and durability.

-

Fermenter: After the ingredients have been boiled in the brew kettle, the next step is fermentation. The fermenter is where the magic happens as yeast interacts with the sugars in the wort, converting them into alcohol and carbon dioxide. Fermenters can be either open or closed vessels, depending on the brewing style and desired outcome. They are typically made of food-grade plastic or stainless steel, allowing for proper fermentation and control of temperature.

-

Mash Tun: The mash tun is a crucial piece of equipment that is used during the mashing process. Mashing involves steeping crushed malt in hot water to break down starches into fermentable sugars. The mash tun provides an insulated environment with temperature control to ensure proper enzymatic activity during the mash. It is equipped with a false bottom or a manifold to separate the liquid wort from the spent grains.

As you embark on your brewing journey, understanding the purpose and functionality of different brewery equipment is essential. From the brew kettle where flavors are extracted to the fermenter where fermentation takes place, each piece of equipment plays a vital role in producing exceptional beer. So, whether you’re setting up a microbrewery or starting as a home brewer, having the right brewery equipment will help you unleash your creativity and craft the perfect brews for any beer enthusiast.